Water jet Machining and Cutting

CALL OR CONTACT US

Phone: 850-983-8600

Email: CPYRITZ@TPR-SYSTEMS.COM

Create shapes and parts with flawless precision while minimizing maintenance time. Patented auto feed technology helps our water jet models work more efficiently and last longer than competing machines. Our Omax water jets can cut just about anything, including mild steel, stainless steel, titanium, aluminum, ceramic, plastic, foam, and copper.

How waterjet cutting works

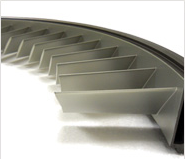

Waterjet cutting is a process that produces shapes by cutting sheet material using a thin,

Advantages

Waterjet cutting is an economical way to cut a very wide range of materials with no tooling costs. The unique process provides reasonably good edge quality, no burrs and usually eliminates the