Learn Our Team & Services

Get to know our experienced team.

At TPR Systems, our dedication and expertise are unmatched. We specialize in in-house manufacturing of turbine parts, including replacement stators, stator components, and stator repairs—all engineered to meet the highest performance standards.

With over 50 years of experience in turbine power generation, we combine innovation, engineering excellence, and precision manufacturing to deliver reliable, high-quality products trusted across the industry. Our commitment to excellence has earned us a reputation for setting the standard in stator manufacturing.

Through hard work and continuous improvement, we are proud to be ISO 9001:2015 / AS9100D certified and recognized as an FAA 145 Repair Station—a testament to our ongoing pursuit of quality and customer satisfaction.

Our Services

We offer a wide range of engineering services, from design to inspection.

Expert Design

At TPR Systems, Inc., our fabrication shop reflects the same principles that define all of our operations—precision, innovation, and reliability. From initial design to final inspection, we apply strict quality control and advanced process management to ensure consistent, dependable results.

Comprehensive Inspection & Quality Assurance

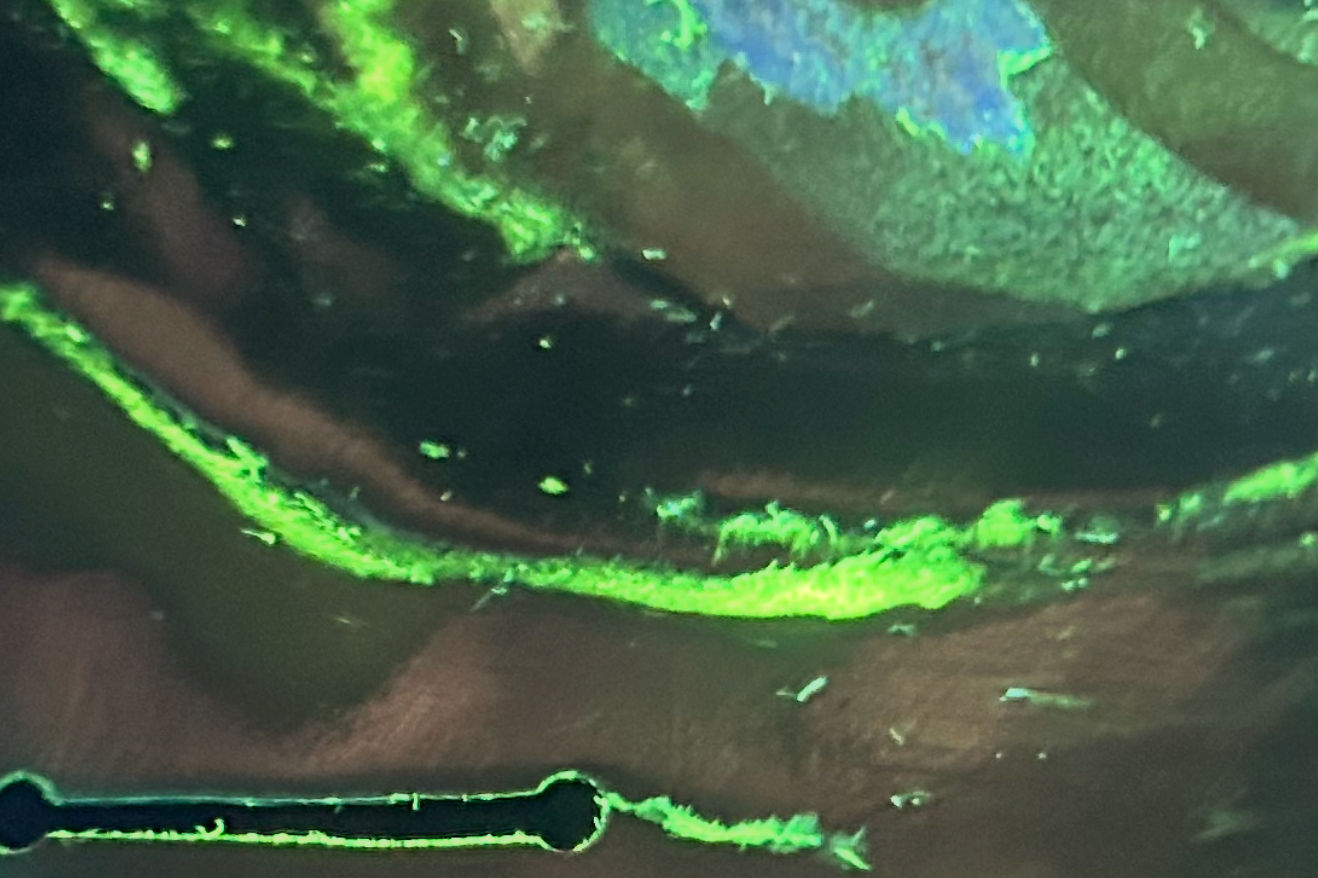

Our inspection capabilities set us apart—combining advanced First Article Inspection (FAI) procedures with comprehensive Non-Destructive Testing (NDT) methods such as dye penetrant and magnetic particle inspection. Using state-of-the-art Computerized Measuring Machines (CMMs) and strict process validation, we verify every component from initial setup through final inspection.

Waterjet Machining and Cutting

Versatile and Economical: Cuts a wide range of materials with no tooling costs.

High-Quality Edges: Produces clean, burr-free cuts that often eliminate the need for secondary finishing.

No Heat Distortion: Because no heat is generated, material properties remain unchanged and edges are unaffected.

Cost-Effective for Short Runs: No custom tooling is required, making waterjet cutting ideal for prototypes, short runs, and production applications.

Custom Fabrication Services

The newly expanded custom fabrication shop at TPR Systems, Inc. is equipped to handle projects of all shapes, sizes, and levels of complexity. Our customers have come to expect the highest standards of quality from our machining and repair divisions—and our fabrication department upholds that same level of excellence.

We are far more than “just another welding shop.” Our team combines creativity, precision, and advanced manufacturing capabilities to deliver exceptional results across a wide range of fabrication projects. Whether large or small, simple or highly complex, every job receives the same meticulous attention to detail and commitment to quality.

Fabrication, Manufacturing & Machining Capabilities

At TPR Systems, Inc., we provide a full range of precision machining, fabrication, and inspection services to support projects of every size and complexity. Our in-house operations allow us to maintain complete control over quality, tolerances, and delivery schedules—ensuring exceptional results every time.

Machining & Manufacturing

Precision Vertical and Trunnion Milling

CNC Turning and Lathe Operations

Multi-Axis Machining for Complex Geometries

3-, 4-, and 5-Axis High-Speed Milling

Electrical Discharge Machining (EDM) – including Form and Wire EDM processes

High-Pressure Waterjet Cutting and Machining

Fabrication & Forming

TIG, MIG, and Induction Welding

Precision Forming and Bending

Hydraulic Forming and Press Operations

CNC-Controlled Brake Forming

Shearing and Material Preparation

Custom Welding and Fabrication Services

Engineering & Design Support

Reverse Engineering and 3D Modeling

Process Optimization and Prototype Development

Heat Treating & Process Control

Controlled Furnace Processing

Custom Heat Treat and Metal Conditioning

Quality Assurance & Inspection

Computerized Measurement and Inspection (CMM)

Non-Destructive Testing (NDT) – Dye Penetrant and Magnetic Particle Inspection

Rigorous Multi-Stage Quality Verification

A Legacy of Quality and Innovation

Originally founded to provide repair services for compressor stators in the power generation industry, TPR Systems quickly recognized that maintaining the highest level of repair quality required complete in-house manufacturing capabilities. Parts sourced from outside vendors simply could not meet our strict standards. By integrating manufacturing and repair under one roof, we gained full control over quality, precision, and performance—allowing us to deliver superior products that outperform the competition in reliability and longevity.

Manufacturing Capabilities

We currently manufacture replacement stators designed for:

– SOLAR Centaur Models 40 and 50

– SOLAR Taurus Models 60, 65, and 70

Repair and Replacement Expertise

– Crack and End Repair

– Vane Replacement (SOLAR Centaur 40 & 50, SOLAR Saturn, TAURUS, MARS)

– Blade Path Replacement

We are one of the few facilities in the country capable of performing blade path replacement on both stators we produce and those manufactured elsewhere. This innovative process offers a cost-effective alternative to purchasing a brand-new stator, saving our customers significant time and expense.

Unmatched Process Control

Every TPR Systems stator undergoes a 1,000-point inspection, including CMM (Coordinate Measuring Machine) verification performed four times throughout the manufacturing process—totaling over 4,000 inspection checks per unit. This ensures each component meets exact specifications individually and integrates perfectly within assembled stators. The result: compressor stators that meet the highest standards of quality, efficiency, and reliability in the industry.

Why Choose Us?

Fast Turnaround Time

Our team of skilled engineers and technicians work efficiently to provide quick solutions for our clients.

Expert Solutions

Our fabrication specialists are skilled in both traditional and modern manufacturing techniques, allowing us to provide custom, high-precision solutions that meet the unique needs of each client. We guarantee that every finished product leaving our facility represents the best possible workmanship and durability in the industry.

Compliance and Quality Assurance

We adhere to all industry standards and regulations to ensure the highest quality of work for our clients.

Contact Info

Let’s Chat

Get in touch with us to discuss your design needs.